Submersible Monobloc Pumps

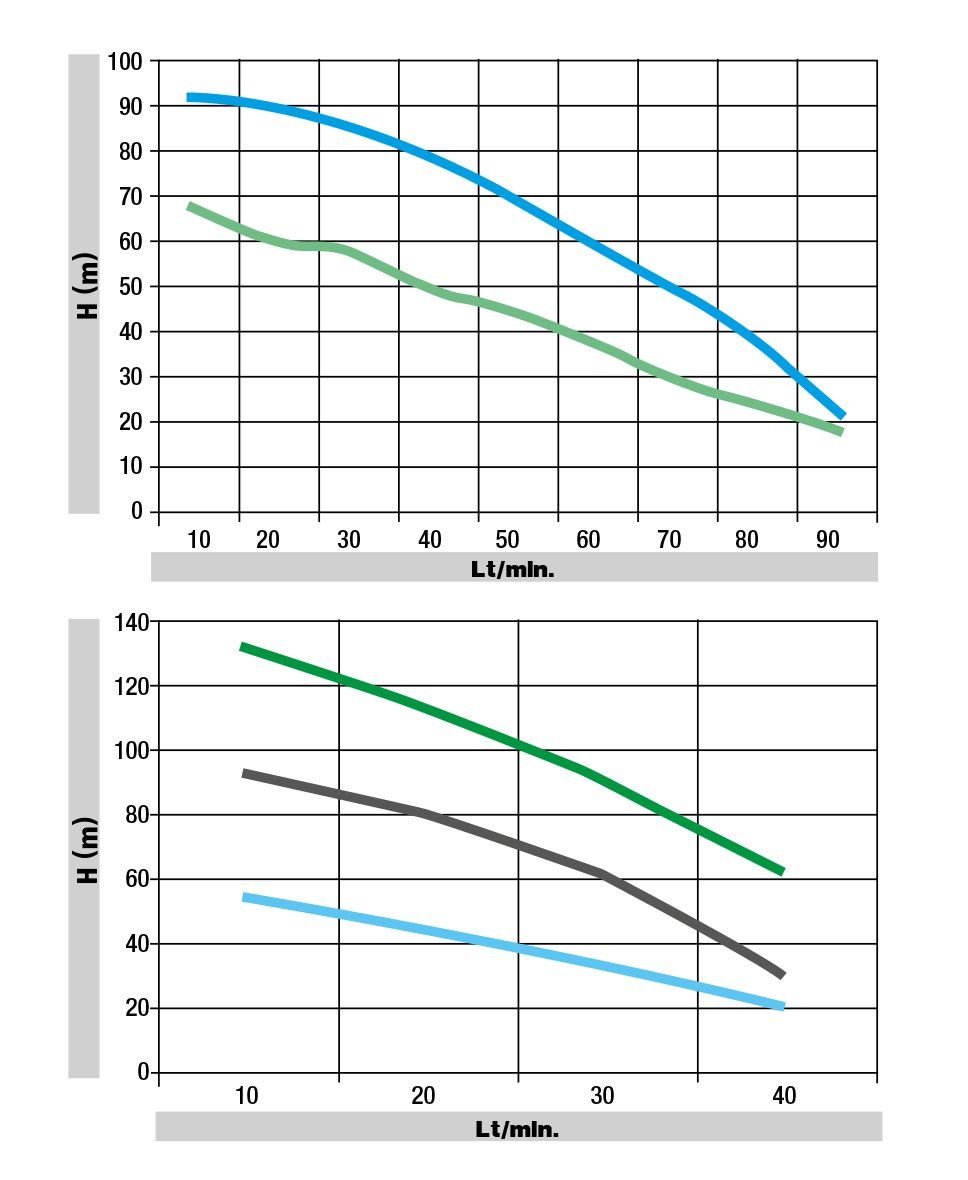

R4

4" MONOBLOCK SUBMERSIBLE ELECTRIC PUMP

USE: Multi-stage submersible electric pumps designed to solve all problems of conveying clean water with temperatures that do not exceed 35 ° C.

- Particularly suitable for irrigation, pressurization systems, emptying tanks and flooded rooms. Industrial and civil uses in general.

- The type of construction allows operation with a minimum level of water.

- Manual or automatic operation with adjustable float.

- In the single-phase version the condenser can be inserted inside the pump or supplied together with the external control panel.

- Made of stainless steel, subjected to severe electrical and hydraulic tests. Max content of sand 60gr / metrocube. Max number of starts now 40.

MATERIALS:

- Pump body, motor casing, handle, AISI 304 stainless steel intake grille;

- Molded brass supports;

- Impellers, diffusers and separators in glass-filled PPOm, each stage is complete with stainless steel wear ring;

- Crankshaft in stainless steel AISI 430;

- Mechanical seal in alumina graphite lubricated with oil;

- On request in SILICIO CARBIDE;

- Special lip seal for sand protection.

ENGINE :

- Asynchronous single phase V.230 50HZ or three-phase V.400 50HZ;

- Other voltages and frequencies on request;

- Insulation class F;

- Internal cooling in mineral oil bath for non-polluting food use;

- External cooling through pumped liquid;

- Built-in thermal protection.

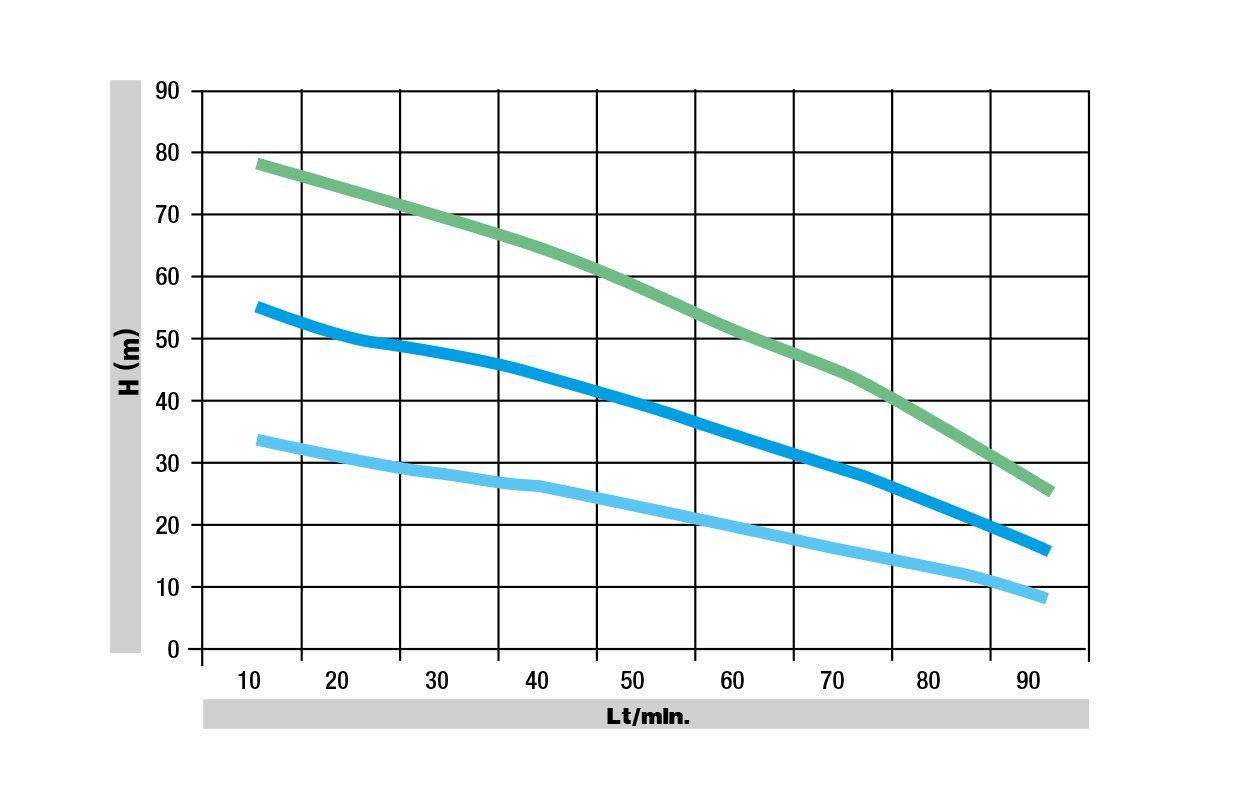

R5

5" MONOBLOCK SUBMERSIBLE ELECTRIC PUMP

EMPLOYMENT: Multi-stage submersible electric pumps designed to solve all problems of conveying clean water with temperatures that do not exceed 35 ° C.

Particularly suitable for irrigation, pressurization systems, emptying tanks and flooded rooms. Industrial and civil uses in general. The type of construction allows operation with a minimum level of water.

Made of stainless steel, subjected to severe electrical and hydraulic tests. Max content of sand 60gr / metrocube. Max number of starts now 40.

MATERIALS:

- Pump body, motor casing, handle, AISI 304 stainless steel intake grille;

- Molded brass supports;

- Impellers, diffusers and separators in glass-filled PPOm, each stage is complete with stainless steel wear ring;

- Crankshaft in stainless steel AISI 4300;

- Mechanical seal in alumina graphite lubricated with oil;

- On request in SILICIO CARBIDE;

- Special lip seal for sand protection.

ENGINE:

- Asynchronous single phase V.230 50HZ or three-phase V 400 50HZ;

- Other voltages and frequencies on request;

- Insulation class F;

- Internal cooling in mineral oil bath for non-polluting food use;

- External cooling through pumped liquid;

- Built-in thermal protection.