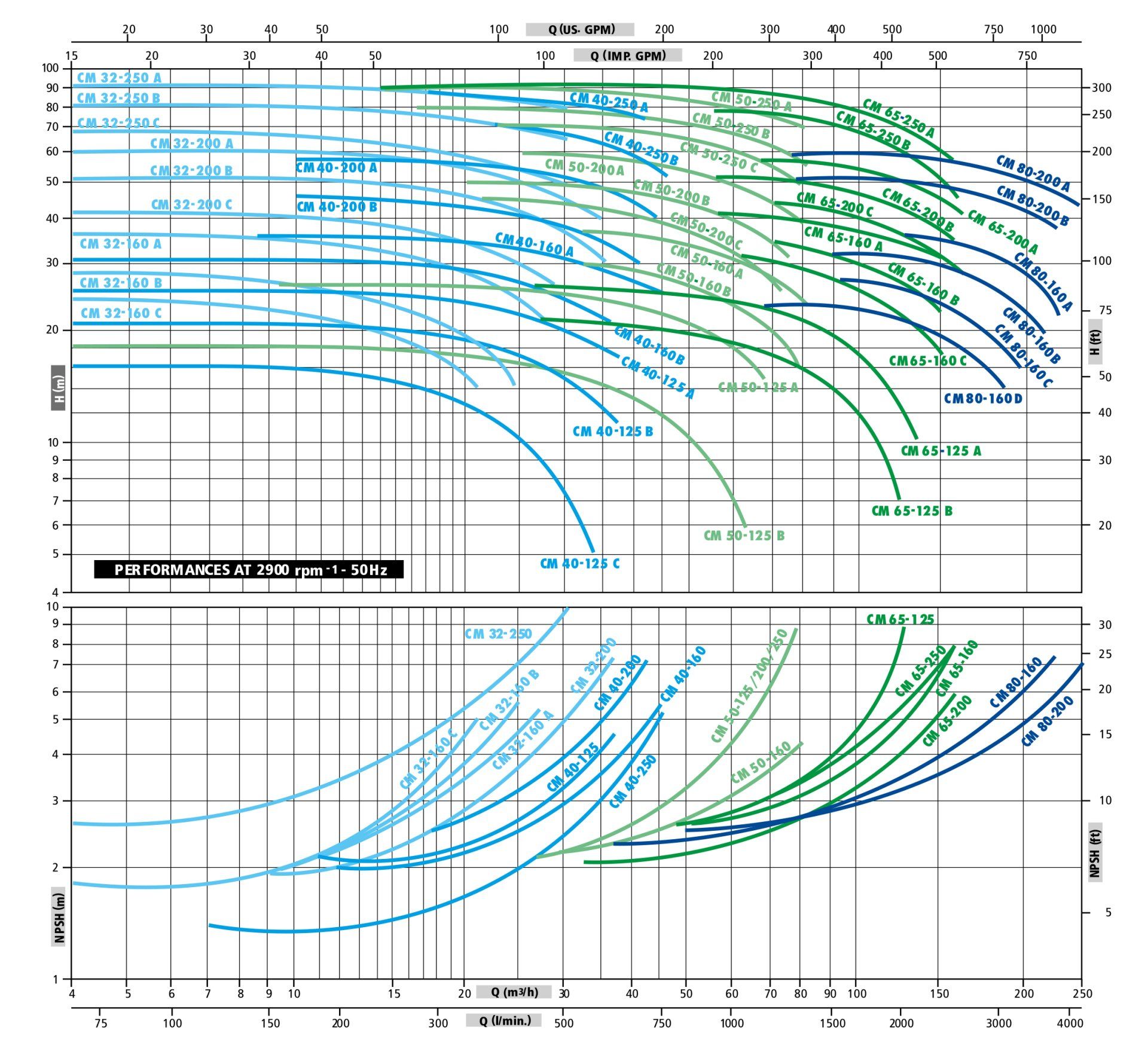

Standardized Electric Centrifugal Pumps

CM normalized

STANDARDIZED CENTRIFUGAL ELECTRIC PUMPS

Horizontal axis monobloc centrifugal pumps built according to EN 733 standards; they are widely used in water supply, in pressurization and fire-fighting systems; as standard they are supplied with counterflange.

FEATURES :

- Cast iron pump body with standardized flanged ports;

- Cast iron motor support;

- Cast iron impeller, on request in bronze;

- Mechanical seal in ceramic - graphite;

- Motor shaft in AISI 304 steel for the hydraulic part;

- Ball bearings;

- Liquid temperature 0 - 90 ° C;

- Working pressure max 10 bar.

ENGINE :

- 2-pole electric induction motor suitable for continuous operation;

- Slats for stator with low specific loss;

- Class F insulation;

- IP 55 protection;

- For all models, thermal protection is the responsibility of the user.

OPTIONAL:

Other operating voltages and frequencies; special mechanical seal; special liquids.